Flexible Moulds

From the creators of the Adaptive Mould, we bring you the next generation of flexible moulds and services.

In 2010, the founder of Kurvatur invented the Adaptive Mould - the first flexible mould to reach the market at scale.

Having invented, sold, installed and serviced more than 100 flexible moulds worldwide, we know more than any other company on to successfully use flexible moulds for production of curved panels.

Maybe you already have a flexible mould? Or maybe you are considering one for a certain project or as an integrated part of your production setup? We can assist you in every aspect.

Flexible moulds

A flexible mould is a reconfigurable robotic mould that enables production companies to fabricate curved surfaces cost-effectively. It eliminates the need for disposable moulds and allow production companies to scale their production rapidly.

A flexible mould is applicable for a range of materials such as composites, concrete, thermoplastics, gypsum, etc. It’s suitable for shaping non-repetitive panels or for creating moulding casts for semi-repetitive requirements.

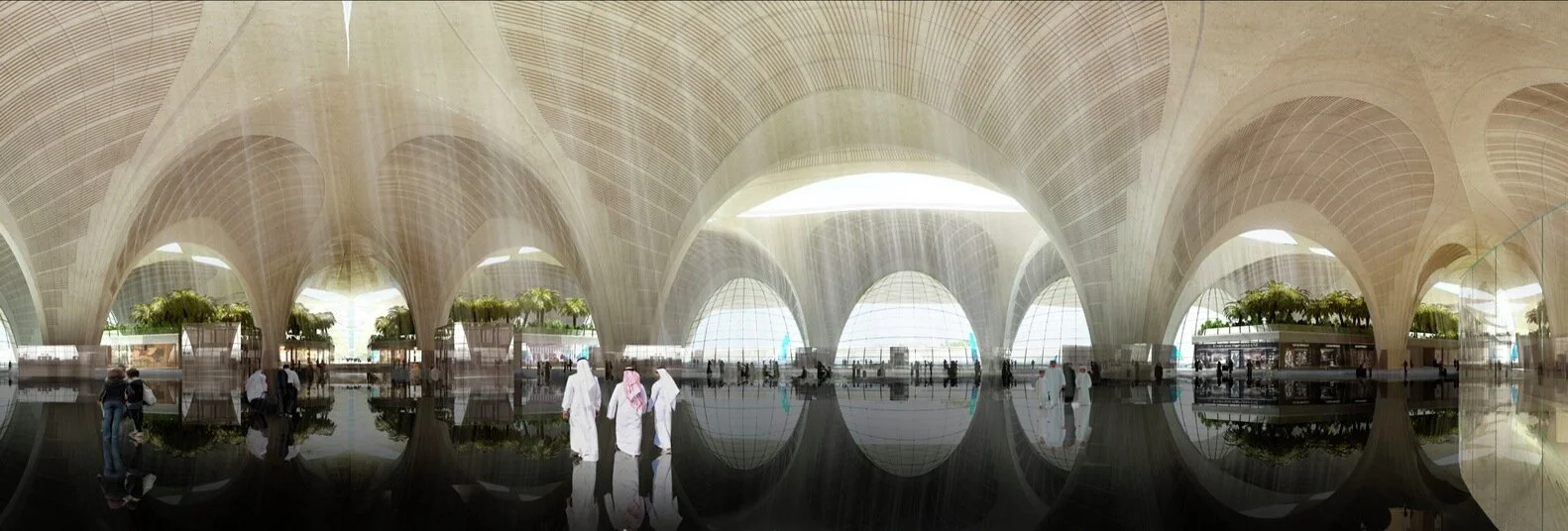

From airports to super yachts. Whenever a project included a flexible mould, we were there to make it happen.

Since 2010, our team has assisted clients around the world to successfully implement and utilise flexible moulds in their production.

Across industries and in a wide range of materials.

Kuwait International Airport. 85 flexible moulds on site for production of 40.000+ unique concrete panels.

Metro Station in Doha. One flexible mould on site for production of curves parts.

Museum of the Future, Dubai, UAE. Three flexible moulds for production of glass fibre wall and ceiling panels.

Sheikh Zayed Museum, Abu Dhabi, UAE. Nine flexible moulds for production of concrete wall and ceiling panels.

Ran Fast 40+ Racing Yacht. One flexible mould for production of 3D foam cores for a light weight boat hull.

Aarhus University, Denmark. One flexible mould for production of a concrete tower (interior decoration).

Flexible mould services

We deliver the products and services that empower our clients to fully utilise the benefits of flexible moulds in their production setup.

Buy a FlexMold.

Save tooling costs by purchasing one of our flexible moulds.

The FlexMold is the next generation of flexible moulds, which we offer at a highly competitive price.

Service and repair.

Never miss a day of production.

If you already have one or more flexible moulds in your production setup, we offer a range of service packages to suit your needs.

Consultancy.

Ask the experts, we are ready to assist.

We can answer almost any question you may have in regards to flexible moulds and curved panel production.

Development.

Flexible moulds are not a one-size-fits-all kind of product.

We help develop the technologies that are required to fully integrate flexible moulds in any production setup.